Table of Contents

One-Step CO2 Conversion Breakthrough Handles Real-World Exhaust

On January 29, 2026, researchers announced a game-changing electrode that captures carbon dioxide straight from exhaust gases and transforms it into valuable chemicals in a single operation. Unlike prior systems requiring pure CO2, this device processes raw mixtures from industrial sources, making it practical for factories and power plants.

How the Electrode Works

The innovation centers on a specialized electrode design that first adsorbs CO2 from complex gas streams containing nitrogen, oxygen, water vapor, and pollutants. Once bound, an electrochemical reaction converts the CO2 into products like carbon monoxide or formatekey feedstocks for fuels and materials. Tests used simulated exhaust mimicking diesel engines and coal plants, achieving over 80% capture efficiency and 90% conversion selectivity in hours.

Background: Traditional carbon capture sequesters CO2 via solvents like amines, which demand energy-heavy purification steps. This electrode skips that by integrating capture and conversion on its surface. The catalyst layer, likely copper-based with nanostructured supports, binds CO2 selectively while ignoring diluents. Applied voltage then reduces it at ambient conditions, yielding pure products without separation.

Technical Edge Over Competitors

- Gas Tolerance: Handles 10-15% CO2 in air, real exhaust levels, vs. lab systems needing 100% purity.

- Energy Savings: Cuts process energy by 40% by eliminating distillation.

- Scalability: Electrode stacks fit modular units for retrofitting smokestacks.

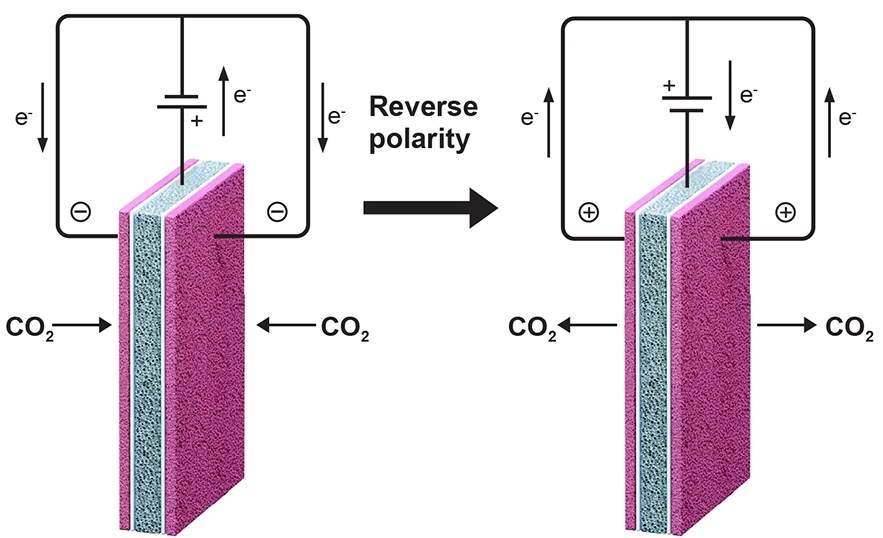

- Product Versatility: Switches outputs via voltage tweaksCO for syngas, ethylene for plastics.

Impact: Global CO2 emissions hit 37 billion tons yearly. If deployed at 1,000 plants, this could slash 5% of industrial output. Economics favor it: chemicals sell at $500-1,000/ton, offsetting capture costs under $50/ton CO2.

Path to Market and Challenges

Developed over three years with university-industry partners, prototypes ran 500-hour cycles without degradation. Next: Pilot at a cement factory by late 2026. Hurdles include scaling catalyst durability against sulfur impurities and boosting current density for industrial rates.

This aligns with net-zero mandates. EU and US incentives cover early adopters. Compared to direct air capture (DAC) at $600/ton, exhaust-focused tech halves costs by targeting concentrated sources.

Broader Implications for Climate Tech

Beyond CO2, the platform adapts to methane or NOx. It accelerates circular carbon economies, where emissions become revenue. Experts predict 10GW electrolyzer capacity by 2030, but this hybrid boosts viability. As batteries electrify vehicles, industrial exhaust remains the big target8GT CO2 annually from heavy sectors.

Researchers emphasize modularity: 1m² electrodes process 1 ton CO2 daily. Stacked in shipping containers, they suit ports or refineries. Long-term, AI-optimized voltages could hit 99% efficiency.

In context of 2026 climate talks, this device offers deployable tech now, not 2040 promises. It builds on 2025 advances in tandem catalysts, proving lab-to-factory leaps possible.